Quick Details:

LK-500S Medium speed WEDM machine Characteristics:

1、The main machine adopts high quality 250 resin sand, which has been tempered many times to eliminate internal stress and keep the accuracy of machine tool unchanged for a long time.

2、Bidirectional constant tension tensioning wire structure, long time processing without manual tensioning wire, so that the precision and surface quality of the processed workpiece has been strongly guaranteed.

3、Filament barrel motion bearing adopts all imported precision bearing, which has longer service life. The guide wheel adopts special high precision guide wheel and all imported bearings, which greatly increases the service life.

4.The filter device of slow-moving silk water tank, special water-based cutting fluid and multi-layer filtering system are adopted. The self-suction pump has better performance and longer service life, which lays a foundation for high precision and roughness of the processing surface.

5.One-stop automatic centralized oil supply device can lubricate X, Y guideways, screw rods, barrel guides and screw rods, and ensure the service life of machine tools.

6.The system is a complete set of WEDM solutions. AutoCut system is composed of AutoCut system software, motion control card based on PCI bus, high reliability, servo drive control motherboard, AC high frequency discharge board and sampling circuit. AutoCut system software includes AutoCAD WEDM module, NCCAD (including WEDM module), CAXA AutoCut plug-in and machine tool control software.

In order to ensure the accuracy of each machine, Longkai uses Renishau laser interferometer to check the positioning accuracy and repetitive positioning accuracy of the equipment. The high-configuration guide wheel and guide nozzle are adopted in the silk hauling system. The reasonable layout completely solves the problem of single side loosening and makes the machined surface achieve uniform roughness.

It can carry out multiple cutting, with the function of user-maintained process library, intelligently control the processing speed and parameters, so as to improve the surface finish and dimensional accuracy, and make multiple processing simple and reliable.

Performance of the whole | Equipment type | Unit | LK-500S |

Fuselage | Host Size (Length *Width *Height) | mm | 1960*1620*2160 |

Total weight | 2300 | ||

Workbench | Workbench size (width x length) | mm | 840*540 |

Travel | X-axis travel | mm | 400 |

Y-axis travel | mm | 500 | |

Z-axis travel | mm | 300 | |

CNC Power Supply | Pulse width | us | 1-250 |

Wire speed | 0-3 | ||

Cutting number | time | 1-7 | |

Mini Mechanical Driving Equivalent | um | 1 | |

Pulse Resolution | um | 0.1 | |

Processing capacity | Spindle stroke (electrically adjustable) | mm | 250 |

Max.cutting slope/workpiece thickness | 6°~30°/80mm | ||

Max. Bearing Capacity of Workbench | kg | 500 | |

Machining accuracy | Location accuracy X/Y | mm | ≤0.01 |

Repeated positioning accuracy X/Y | mm | ≤0.005 | |

Multi-tool Cutting Accuracy | mm | ≤0.005( 40mm,Cut one and repair two.MaterialSKD11 or Cr12,HRC58) | |

Optimum Surface Roughness | um | Ra≤1.0(MaterialSKD11 or Cr12,HRC58) | |

Maximum cutting efficiency | mm²∕min | ≥220 | |

Common cutting efficiency | mm²∕min | ≥140 | |

Max. Processing Current | A | ≥6-8 | |

Processing efficiency | No-load Voltage of Machining Power Supply | V | 100 |

Power consumption | KW | ≤2.3 | |

Wire traveling system | Electrode wire diameter | mm | ∮0.12-∮0.2 |

Wire barrel traveling speed | frequency control | ||

Tightening method | Two-way automatic tightening | ||

Wire travelling speed | m/s | 3-12 | |

Working groove | Filtration accuracy | um | <10 |

Filtration mode | Slow-Walking Filtration | ||

Working fluid | Special cutting fluid | ||

Environment and electricity | Electric power | 380V±10% / 50/60Hz / 2kVA | |

Temperature | T15-30℃ / humidity40-80% | ||

Pressure | kpa | 86-106kpa |

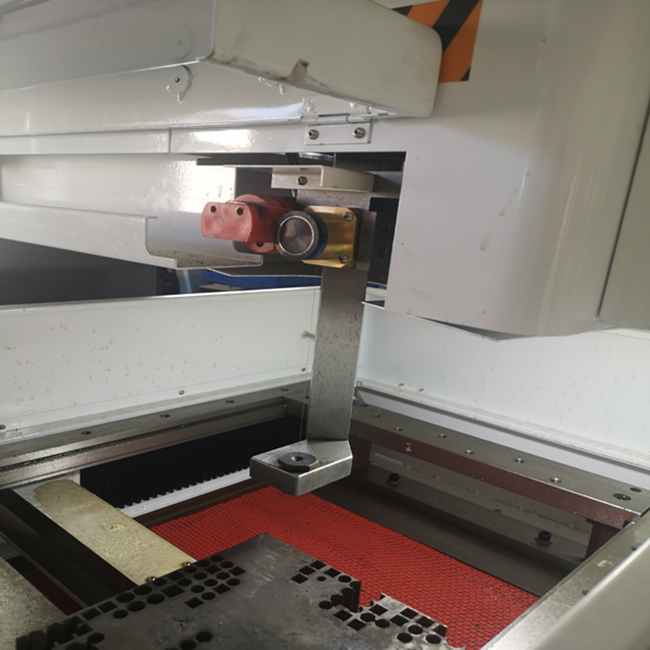

sample pictures