Quick Details:

VMC-650 Turning milling machine center

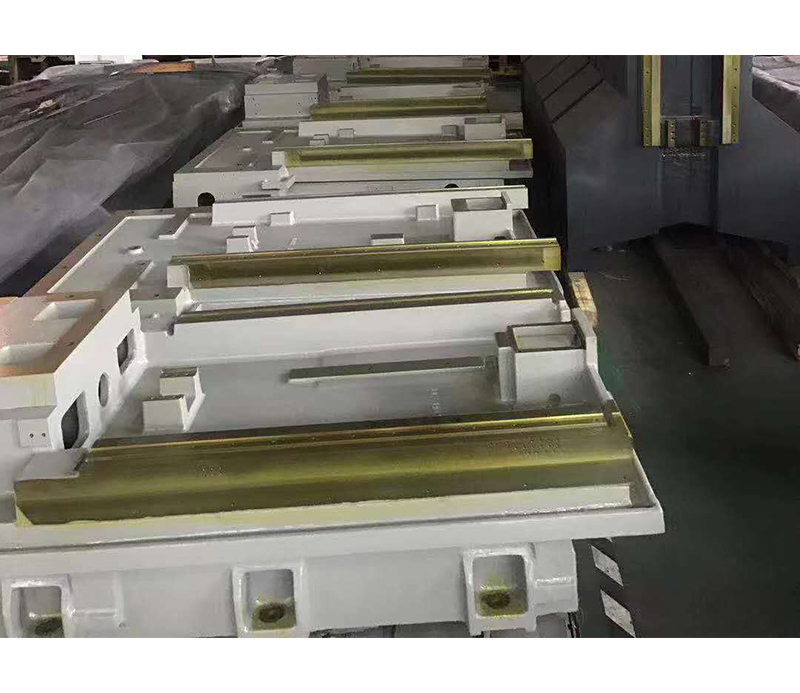

The high-precision vertical machining center can automatically complete the processing of milling, boring, drilling, expanding, tapping (rigid tapping) and other processes. It is widely used, especially suitable for processing various complex two-dimensional and three-dimensional concave convex models and complex cavities and surfaces. It is suitable for medium and small batch production of precision parts such as plates, plates and shells. It is widely used in the processing of 3D complex parts in aviation, aerospace, auto parts and molds.

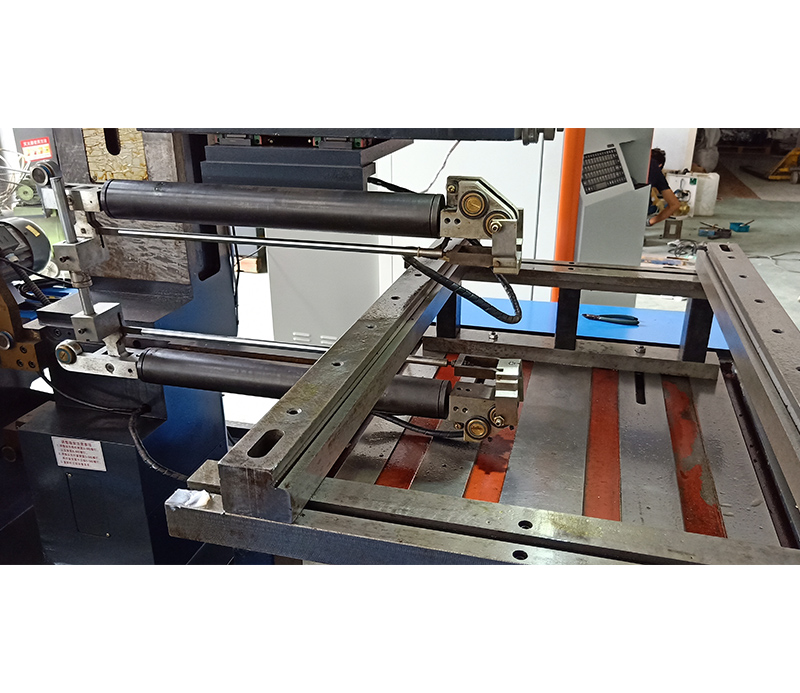

The vertical machining center adopts direct connected high-speed spindle and herringbone column design to improve the seismic capacity of the whole machine, so that the machining center can maintain high-precision machining standards under the condition of high-speed machining. It is a high-speed vertical machining center widely used in the machining of CNC precision parts.

Model | VMC-650 |

X-axis Travel mm | 600 |

Y-axis Travel mm | 500 |

Z-axis Travel mm | 500 |

Spindle end to table mm | 110-610 |

Spindle speed rpm | 10000 |

Spindle motor power kw | 7.5 |

Three axis motor power kw | X2/Y2/Z2 |

Table area mm | 500*800 |

T-groove (groove * width * center distance) mm | 3-18*144 |

X-axis rapid displacement mm/min | 24000/36000 |

Y-axis rapid displacement mm/min | 24000/36000 |

Z-axis rapid displacement mm/min | 18000/36000 |

feed rate mm/min | 1-8000 |

Spindle taper | BT40 |

Prop quantity | 24 |

Maximum tool diameter mm | 80 |

Maximum tool length mm | 200 |

Tool weight kg | 7 |

Tool magazine category | Bamboo hat / knife arm |

Air pressure source kg/cm² | 5.5 |

Bearing of worktable kg | 600 |

Machine tool weight kg | 5500 |