Quick Details:

VMC-3025 vertical machining center

Vertical machining center is a high-precision machining center of our company. The machine adopts a high-precision CNC turntable originated in Taiwan, which can process small and medium-sized parts as well as indexing and rotary processing. It is most suitable for multi task sequential processing such as milling, drilling, boring, reaming, tapping, two-dimensional and three-dimensional curved surfaces of parts. It has the good performance of completing box hole system and plane processing in one clamping. It is also especially suitable for turning boring of box hole, It is widely used in automobile, internal combustion engine, aerospace, household appliances, general machinery and other industries.

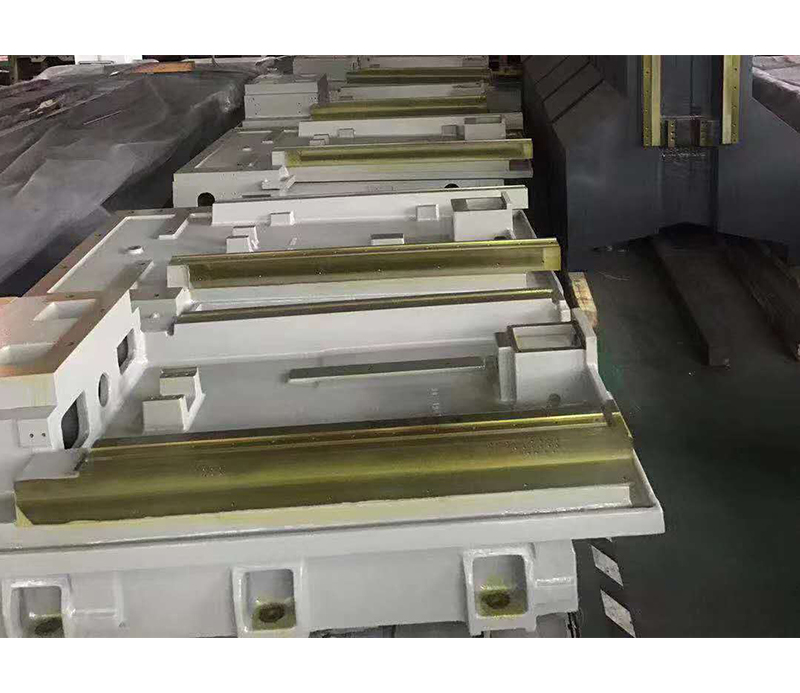

1. HT300 cast iron shall be used for main foundation parts such as base, sliding seat, workbench, column and spindle box; The substructure is a box structure, and the compact and reasonable symmetrical reinforcement structure ensures the high rigidity, bending resistance and damping performance of the foundation parts; A-span column and internal grid reinforcement effectively ensure the rigidity and accuracy of z-axis strong cutting; The basic parts are molded with resin sand and aging treatment, which provides guarantee for the stability of long-term service performance of the machine tool.

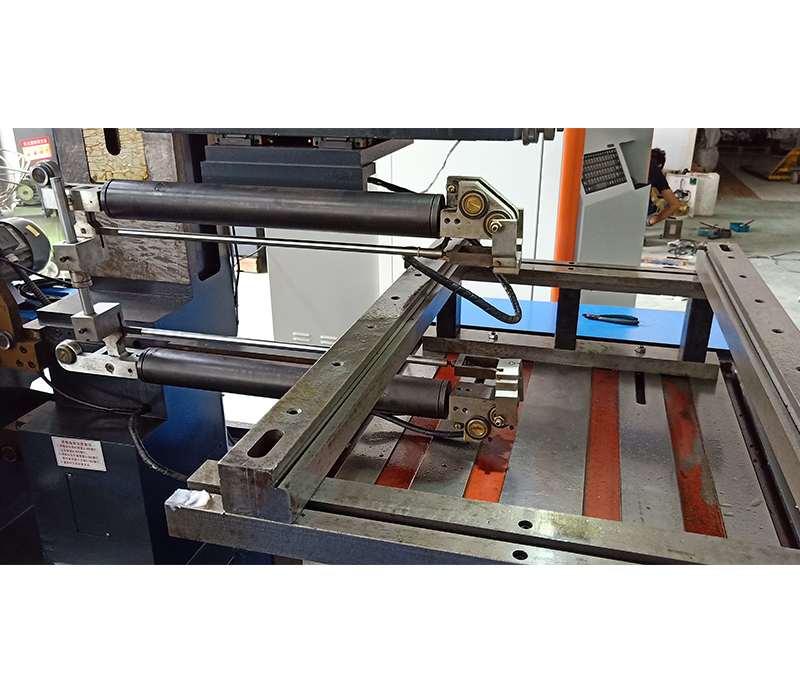

2. The X, Y and Z three-way guide rails are plastic pasted rectangular guide rails, which have the characteristics of high speed, high rigidity, low friction, low noise and low temperature rise change. They cooperate with automatic forced lubrication to improve the accuracy and service life of the machine tool.

3. Add counterweight in Z direction to ensure smooth and stable movement of headstock; The z-direction drive motor is equipped with power loss braking device.

Model | VMC-3025 |

X-axis Travel mm | 3000 |

Y-axis Travel mm | 2500 |

Z-axis Travel mm | 1000 |

Spindle end to table mm | 260-1260 |

Spindle speed rpm | 4000/6000 |

Spindle motor power kw | 25 |

Three axis motor power kw | X7/Y4.5/Z4.5 |

Table area mm | 2300*3000 |

T-groove (groove * width * center distance) mm | 11-28*200 |

X-axis rapid displacement mm/min | 10000 |

Y-axis rapid displacement mm/min | 10000 |

Z-axis rapid displacement mm/min | 10000 |

feed rate mm/min | 1-5000 |

Spindle taper | BT50 |

Prop quantity | 50 |

Maximum tool diameter mm | 300 |

Maximum tool length mm | 315 |

Tool weight kg | 20 |

Tool magazine category | Disc type |

Air pressure source kg/cm² | 10 |

Bearing of worktable kg | 4500 |

Machine tool weight kg | 42000 |