Quick Details:

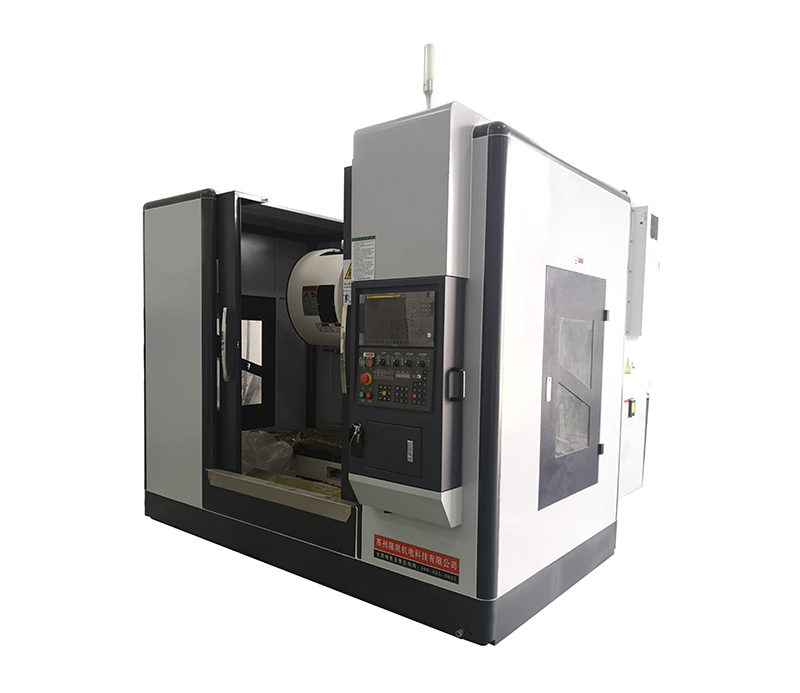

VMC-1060 super speedy cnc machine center

VMC-1060 super speedy cnc machine center is a cost-effective vertical machining center developed by our company for small hardware parts and products. The machine tool has the advantages of strong structure, stable precision, low failure rate and good reliability. It is a sharp tool for processing small products.

The three axes of the machining center adopt linear slide rail, which has the characteristics of high rigidity, high positioning accuracy, low noise and low friction. It can be used for rapid displacement (48m / min) to obtain the best circular accuracy.

The main structure casting of the machining center adopts high-quality mihanna cast iron, which has stable organization and permanently ensures the quality; The casting is calculated and analyzed by computer through finite element analysis method, and the reasonable structural strength and the matching of stiffeners provide high mechanical rigidity; The super wide base and column are box structure, the saddle is widened and lengthened, the heavy load full support design, and the structure is solid, which can ensure the heavy load capacity during processing; The main shaft head is reinforced with ribs, and the contact length ratio between the main shaft head and the column is appropriate to provide stable support for the main shaft.

The machine is equipped with anti-collision device, which can absorb the vibration caused by the impact caused by workers' misoperation, minimize the impact damage and ensure the original accuracy; The machine adopts oil-water separation design, which can effectively separate the lubricating oil from the cutting fluid and prevent the deterioration of the cutting fluid due to mixing and affect the processing quality; The machine adopts Taiwan's high-precision high-rigidity high-precision spindle. The belt spindle has strong rigidity and high reliability. The direct spindle has high speed, high efficiency, high precision, low noise and low vibration, which fully meets the needs of users.

Model | VMC-1060 |

X-axis Travel mm | 1100 |

Y-axis Travel mm | 600 |

Z-axis Travel mm | 600 |

Spindle end to table mm | 70-670 |

Spindle speed rpm | 10000 |

Spindle motor power kw | 11 |

Three axis motor power kw | X3/Y3/Z3 |

Table area mm | 600*1300 |

T-groove (groove * width * center distance) mm | 5-18*100 |

X-axis rapid displacement mm/min | 24000/36000 |

Y-axis rapid displacement mm/min | 24000/36000 |

Z-axis rapid displacement mm/min | 18000/36000 |

feed rate mm/min | 1-6000 |

Spindle taper | BT40 |

Prop quantity | 24 |

Maximum tool diameter mm | 100 |

Maximum tool length mm | 305 |

Tool weight kg | 7 |

Tool magazine category | Bamboo hat / knife arm |

Air pressure source kg/cm² | 6 |

Bearing of worktable kg | 1000 |

Machine tool weight kg | 8000 |