Quick Details:

CNC milling machine

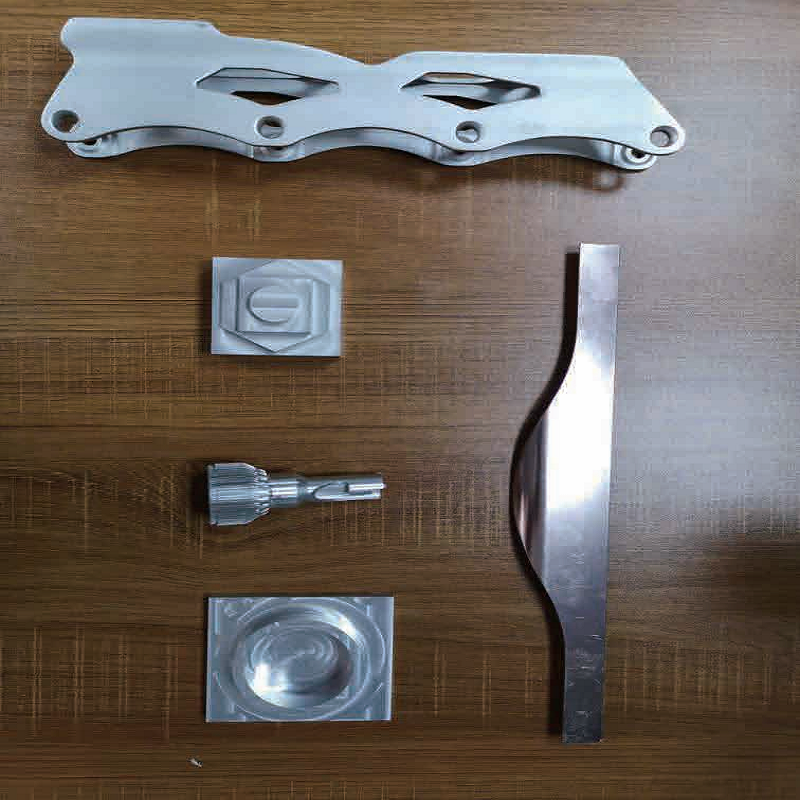

Product introduction and Application

The product is X, Y, Z, the fourth axis, four axis servo control vertical CNC milling machine, rectangular guide load, high precision, compact and reasonable structure and dimensions, the spindle is 3P motor driven by belt. It can complete drilling, milling, boring, expanding, reaming and other processes for all kinds of complex parts such as discs, plates, shells, cams and molds. It is suitable for the production of multi variety, medium and small batch products, and can meet the processing of complex and high-precision parts. It can be equipped with a fourth rotating shaft to meet the processing requirements of special parts.

LK-40 | Parameters |

Dimension of worktable | 1470*320mm |

Maximum load of worktable | 350KG |

X / Y / Z axis stroke | 800/340/400+127mm |

Fourth axis rotary table | Rotation diameter 170 |

Distance between spindle center and column guide | 320mm |

Distance between spindle end face and worktable | 100-500mm |

Spindle taper hole | R8/NT40 |

Spindle diameter | Φ85MM |

Spindle speed | 80-4500(5440)r/min |

Fast moving speed (x, y, z) track | 12/12/12M/min |

Cooling motor | 125w |

Machine weight | 1500-1650kg |

Machine tool dimensions (L) × wide × (high) | 2200*1800*2000mm |

One way positioning accuracy (full length of X, y and Z axes) | 0.03/300MM |

One way repeat positioning accuracy | 0.02mm |

Main motor power | 3.7KW(5HP) |

Numerical control system | SYNTEC Numerical control system |