Quick Details:

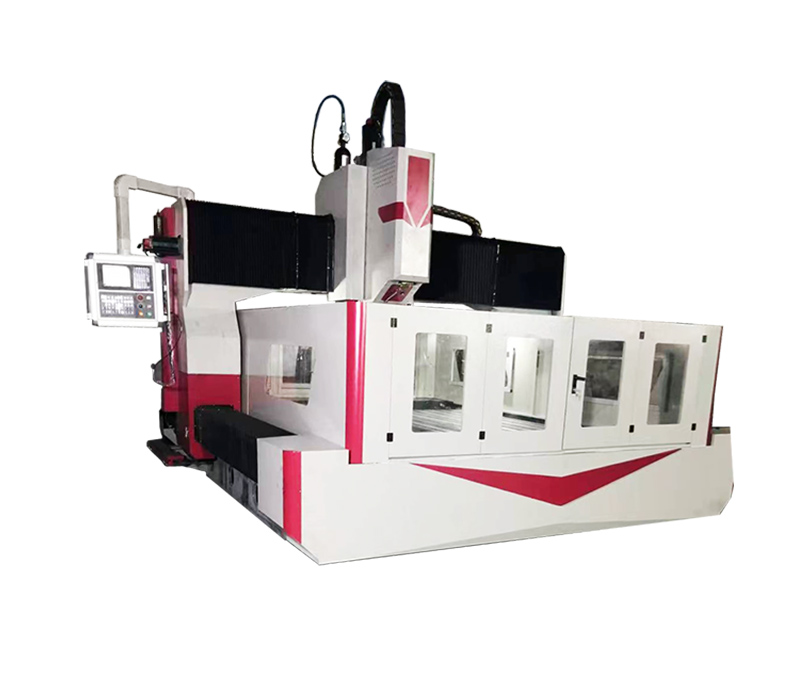

LK-3020 CNC drilling and milling machine

Machine structure:

1、The machine tool is mainly composed of bed body, work table, gantry, power head, numerical control system and cooling system.

2、The gantry CNC drilling machine is fixed in the form of a bed workbench and moves in the form of a gantry.

(damping gantry structure)

3.Bed, column, workbench, gantry is HT250 casting structural parts, bracket is rectangular tube welding parts, high temperature annealing before processing, secondary annealing after semi-finishing to remove stress, and then finishing, can ensure the accuracy of machine tool, bed The T-shaped groove is finished by milling the whole cast iron workbench, and the countertop is CNC-finished to ensure the precision of the work surface.

4、The gantry CNC drilling machine has three CNC axes. The bed is equipped with heavy-duty linear guides. The gantry can be moved longitudinally along the guide rails (x-axis). The gantry beam is also equipped with linear guides. The slide can be moved along the guide rails (y-axis). The slide plate is equipped with a slider, the power head is equipped with a guide rail, the power head can be vertically moved on the slide plate (z axis), and the x, y, and z axes are driven by a numerical control servo motor and a ball screw.

5、The power head spindle adopts precision spindle and servo spindle motor drive, which can be steplessly regulated according to requirements. The spindle can be used to clamp the drill tap or milling cutter through the BT40 chuck, and it is equipped with a pneumatic cutter cylinder to realize one-button tool change with higher precision and high-speed cutting.

6、The machine tool is water-cooled, equipped with coolant supply, recovery, circulation system, and equipped with automatic oil lubrication system to ensure smooth and long-term effective operation of linear guides and ball screws.(Equipped with high-speed inner water-out spindle, it can use central water-discharging tools such as: U-drill, shovel drill, crown drill, alloy inner-cooled drill, core drill, etc.)

7.The control adopts Kane's CNC system. The electric drive is driven by high-precision absolute value series servo motor. It is equipped with RS232 interface and color display. It has Chinese operation interface. It can input workpieces on site/external USB. It is easy to operate and equipped with all-digital high-speed handwheel. Make your operation easier and faster.

| model | LK-3020 |

| L*W(mm) | 3000×2000 |

| Max. thickness of workpiece(mm) | 200 |

| Spindle taper hole | BT50 |

| Borehole diameter(mm) | Φ3-Φ80 |

| Tapping diameter(mm) | M4-M36 |

| Servo Spindle Motor Power(kw) | 30 |

| torque(N.m) | 400 N.m |

| Distance from lower end of spindle to worktable | 350-800 |

| Max. stroke of X-axis(mm) | 2000 |

| X-Axis Moving Speed(m/min) | 0~8 |

| X-axis servo motor power(kw) | 2.4*2(15N.m) |

| Max. stroke of Y-axis(mm) | 3000 |

| Y-Axis Moving Speed(m/min) | 0~8 |

| Y-axis servo motor power(kw) | 2.4*1(15N.m) |

| Max. stroke of Z-axis(mm) | 450 |

| Z-Axis Moving Speed(m/min) | 0~4 |

| L*W*H(mm) | 6600×4600×3350 |

| Gross weight(t) | (about)23 |